Selecting the right warehouse roll up door is crucial for operational efficiency. According to a recent report by Grand View Research, the global market for roll-up doors is expected to reach $2.85 billion by 2025. This indicates a growing recognition of their importance in various industries. Industry expert Mark Johnson emphasizes, "Choosing the right door can significantly impact productivity and safety."

Understanding the options available can be overwhelming. Different materials, sizes, and insulation levels affect performance. A poorly chosen warehouse roll up door can lead to inefficiencies and increased costs. It's essential to consider specific needs, such as climate and traffic volume. Each detail matters in ensuring that the door aligns with your operational requirements.

Despite the apparent benefits, many businesses overlook this decision. They may rush the process or fail to consult experts. As a result, they might face frequent maintenance issues. Recognizing the importance of a proper selection is the first step towards optimizing warehouse operations. Consider the long-term implications of your choice.

Selecting the right warehouse roll-up door is crucial for any business. When choosing, think about the size and type of your loading area. Will you be using forklifts often? Larger openings might be necessary. Small spaces may need compact designs. Consider the material as well. Steel doors are durable but can be heavy. Lightweight options are easier to operate but may lack strength.

Don’t overlook insulation properties. If your warehouse stores temperature-sensitive products, quality insulation is a must. Additionally, think about security features. Some doors may have weak locks, making them vulnerable. Evaluate your needs carefully to avoid future problems. The cost is another factor. While budget constraints exist, investing in a higher-quality door can save money long-term. Quality products often lead to fewer maintenance issues.

Finally, reflect on the door's installation. A poorly installed door can lead to operational delays. Perhaps assess how often the door will be used. More frequent use might require more robust features. Don't rush the decision-making process. Take time to evaluate options that best fit your specific operational needs.

When choosing a warehouse roll-up door, understanding different types is crucial. There are several widely recognized options. Firstly, there are steel roll-up doors. They are durable and provide excellent security. According to industry data, steel doors can last over 20 years with proper maintenance. However, they can be heavy and require more energy to operate.

Another option is the aluminum roll-up door. These are lighter and resist rust, making them suitable for industries exposed to moisture. Studies show that aluminum doors can reduce energy costs by up to 30%. Yet, they may lack the ruggedness of steel, leading to potential concerns in high-impact environments.

Fabric roll-up doors offer flexibility and quick access. They are ideal for environments where speed is essential, like distribution centers. They can open and close in seconds. However, they may not provide the level of protection needed in some applications. It’s essential to weigh the benefits against potential trade-offs. Each type of door comes with challenges. Understanding your specific needs will help navigate this decision. Balancing security, energy efficiency, and durability is key.

When selecting a warehouse roll up door, security features should be a top priority. A strong door can deter theft and vandalism. Look for options made from durable materials like steel. Many doors come with reinforced locking mechanisms. This adds an extra layer of protection for your goods.

Consider the door’s design as well. Does it have windows? While they allow natural light, they can also create vulnerabilities. Decide if visibility is worth the risk. Also, assess if the door has an alarm system. An alarm can alert you or authorities during a breach.

Installation matters too. Poorly installed doors may lead to gaps. These gaps could be entry points for intruders. Regular maintenance is essential to keep the door functional. Failing to check for wear and tear can lead to security breaches. Reflection on these aspects ensures that your investment provides the protection you need.

| Door Type | Material | Security Level | Insulation | Price Range |

|---|---|---|---|---|

| Standard Roll Up Door | Steel | Medium | No | $800 - $1,200 |

| Insulated Roll Up Door | Aluminum | High | Yes | $1,200 - $1,800 |

| Fire Rated Roll Up Door | Steel | Very High | No | $1,500 - $2,500 |

| Security Grille Roll Up Door | Aluminum | High | No | $1,000 - $1,600 |

| Custom High-Speed Roll Up Door | Fabric/Steel | Medium | Yes | $2,000 - $3,500 |

When selecting a roll-up door for your warehouse, energy efficiency can significantly impact your operational costs. Insulated doors are a smart choice for maintaining temperature control. These doors use materials that reduce heat transfer, helping keep indoor climates stable. In turn, this can lower heating and cooling expenses.

It’s important to assess insulation ratings. Look for doors with higher R-values, which indicate better insulation. However, not all insulated doors perform equally. Real-world testing often reveals discrepancies. Some doors may not deliver their promised efficiency.

Cost is another factor to consider. Insulated doors generally come with a higher upfront price but offer long-term savings. Balancing your budget with energy-saving features is crucial. Evaluating your specific needs may reveal gaps in best practices. Sometimes, you need to rethink your current setup and explore options more diligently.

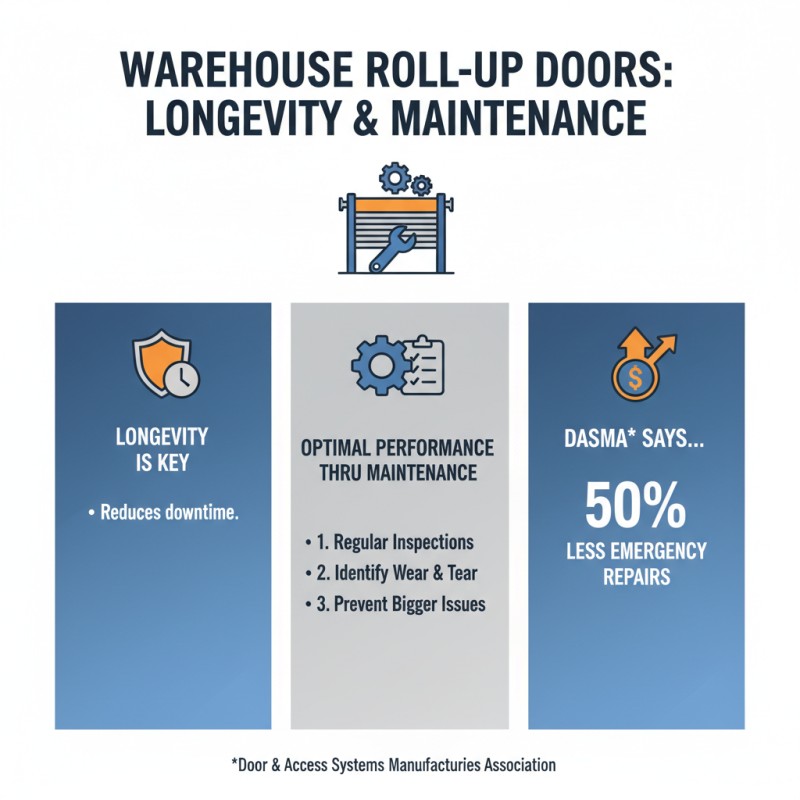

When selecting a warehouse roll up door, longevity is key. Regular maintenance is vital for optimal performance. According to the Door and Access Systems Manufacturers Association (DASMA), routine inspections can reduce emergency repairs by up to 50%. A simple check can identify wear and tear that could lead to bigger issues later.

Durability often depends on materials used. Steel and aluminum doors offer strength and resilience. However, they require different maintenance levels. Steel can rust if not properly treated, while aluminum can dent easily. A yearly inspection may not be enough for high-traffic environments. Monitoring frequently ensures peak functionality. It is essential to know what your door needs.

Sometimes, the installation can impact longevity. Improper setup might cause misalignment, leading to increased wear. Manufacturers suggest training for staff to handle doors correctly. Ignoring these details could shorten door lifespan. A small investment in training can pay off in the long run. Be mindful of these factors.

Since 1984, Thermostop has been a reputable manufacturer of Industrial Sectional Doors, Cold Storage Doors and Specialty Doors such as Impactable Breakaway doors, Acoustic Doors and Ballistic Doors.

Contact